Using our FullSpectrum Laser, Nick finished a patron project making some twenty odd personalized center-pieces for a wedding. Such an adorable and easy personal gift idea, we were glad to be able to help out!

If you have an idea or lasercut project, sign up from a consultation:

https://unt.az1.qualtrics.com/jfe/form/SV_aW5PLHbePpqUbMF

or submit a work request:

https://unt.az1.qualtrics.com/jfe/form/SV_czS3nZhPUhIK1QF

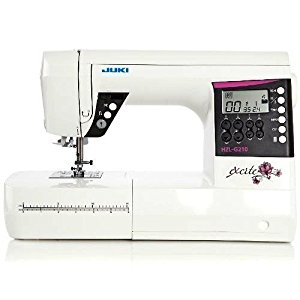

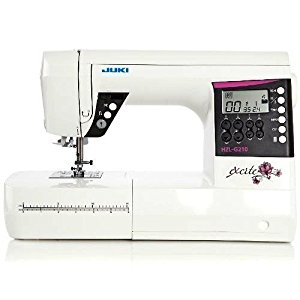

Whether you’re a student working on a design project or a sewing enthusiast looking to expand your skills, we have the tools you’ll need to make your creations come to life. We have created bean bags, purses and quilts. Students have created monograms on items to personalize them. Check out our two high-end sewing machines and work with them in the Factory!

We have the Juki Excite Hzl-g210, a computerized sewing machine with small bobbins and needles along with different type of presser feet.

Also check out our Memory Craft 6500P sewing machine which is a computerized sewing and quilting machine. We also have small number of bobbins and Janome needles of varying sizes along with different types of presser feet and accessories.

Also check out our Memory Craft 6500P sewing machine which is a computerized sewing and quilting machine. We also have small number of bobbins and Janome needles of varying sizes along with different types of presser feet and accessories.

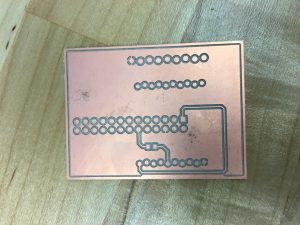

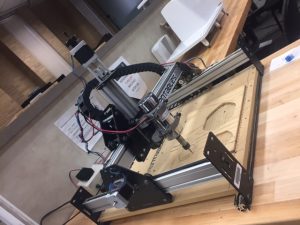

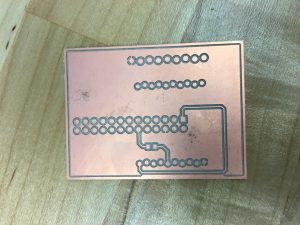

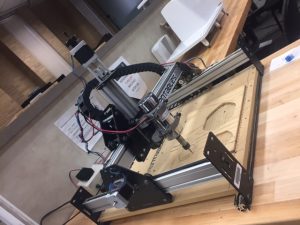

The Factory has two CNC machines which have been really busy this semester, from stamp creation workshops to PCB boards these machines have been hard at work!

Below is information about each machine:

Shapeoko Machine: The CNC Shapeoko Machine is a milling tool available to mill common materials such as wood, plastics, soft/ non-ferrous metals, and a plethora of other materials. CNC, meaning Computer Numerically Controlled, together with a series of motors and drive components to move and control the machine axes, executing the programmed motions.

Shapeoko Machine: The CNC Shapeoko Machine is a milling tool available to mill common materials such as wood, plastics, soft/ non-ferrous metals, and a plethora of other materials. CNC, meaning Computer Numerically Controlled, together with a series of motors and drive components to move and control the machine axes, executing the programmed motions.

OtherMill Pro: The OtherMill Pro is a personal milling machine used to create PCB’s (Printed Circuit Boards) without the hassle of waiting for the board to be printed from an outside source. It also works with various materials such as wood and plastics, on a much smaller scale. The Othermill Pro is the fastest way to prototype high-precision PCBs in-house. Milling directly from Gerber files, the Othermill Pro handles double-sided PCBs with a variation of milling bits and can create your projects within minutes.

If you have a CNC project , you can submit a work request through The Factory website. Then an appointment will be scheduled with a Maker to train you on how to use the equipment to complete your project. Also, The Factory offers workshops on the topic.

The next CNC Easel Workshop For the Shapoko is schedule at 1pm on March 1, 2017. Registration is recommended to to limited sitting but not required.

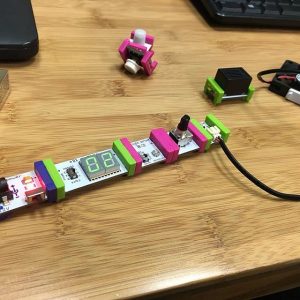

My name is Nicholas Carter, I’m a fourth year double studio arts major focused in New Media Arts & Interdisciplinary Studies and a Philosophy minor currently in the finishing stages of my undergraduate career. As a studio art major focused in interaction and practices with computer software technology and physical computing aspects, it’s only natural that I stumbled across a place much like The Factory. My previous experience with laser cutting, and 3D modeling can be attributed to my innate curiosity, but also sharp visual comprehension skills as well. My skills and practices revolve around laser cutting/engraving, microcontrollers and physical computing applications to real life situations. While those tend to be my focuses, as mentioned before, the kid in me oftentimes causes me to spend time and obtain new skills here as well. Those interests range largely from video game development and environmental design, various 3D modeling programs, and hopefully one day 3D model animation. I even find myself checking out equipment from The Factory for the sole purpose of learning something just because I can. I’ve done so much as lasercut signage for residents halls, housing/structure components, wedding photos, nameplate centerpieces and graduation gifts. In addition to that I’ve interacted and used various electrical components with Microcontrollers to execute simple, but efficient tasks. I’m always willing to learn new things and I love the accessibility of The Factory and the opportunity to benefit from all the resources provided here. With the gradual development of The Factory after 2+ years, and the increasing attention it has received, I’m eager to see how much recognition and growth this makerspace receives in the foreseeable future. Nick specializes in working with the lasercutter, LittleBits kits, Arduino, and visualizations. He is learning more about Unity Gamer Engine and IR sensors!

OtherMill Pro: The OtherMill Pro is a personal milling machine used to create PCB’s (Printed Circuit Boards) without the hassle of waiting for the board to be printed from an outside source. It also works with various materials such as wood and plastics, on a much smaller scale. The Othermill Pro is the fastest way to prototype high-precision PCBs in-house. Milling directly from Gerber files, the Othermill Pro handles double-sided PCBs with a variation of milling bits and can create your projects within minutes.

If you have a CNC project , you can submit a work request through The Factory website. Then an appointment will be scheduled with a Maker to train you on how to use the equipment to complete your project. Also, The Factory offers workshops on the topic.

The next CNC Easel Workshop For the Shapoko is schedule at 1pm on March 1, 2017. Registration is recommended to to limited sitting but not required.

My name is Nicholas Carter, I’m a fourth year double studio arts major focused in New Media Arts & Interdisciplinary Studies and a Philosophy minor currently in the finishing stages of my undergraduate career. As a studio art major focused in interaction and practices with computer software technology and physical computing aspects, it’s only natural that I stumbled across a place much like The Factory. My previous experience with laser cutting, and 3D modeling can be attributed to my innate curiosity, but also sharp visual comprehension skills as well. My skills and practices revolve around laser cutting/engraving, microcontrollers and physical computing applications to real life situations. While those tend to be my focuses, as mentioned before, the kid in me oftentimes causes me to spend time and obtain new skills here as well. Those interests range largely from video game development and environmental design, various 3D modeling programs, and hopefully one day 3D model animation. I even find myself checking out equipment from The Factory for the sole purpose of learning something just because I can. I’ve done so much as lasercut signage for residents halls, housing/structure components, wedding photos, nameplate centerpieces and graduation gifts. In addition to that I’ve interacted and used various electrical components with Microcontrollers to execute simple, but efficient tasks. I’m always willing to learn new things and I love the accessibility of The Factory and the opportunity to benefit from all the resources provided here. With the gradual development of The Factory after 2+ years, and the increasing attention it has received, I’m eager to see how much recognition and growth this makerspace receives in the foreseeable future. Nick specializes in working with the lasercutter, LittleBits kits, Arduino, and visualizations. He is learning more about Unity Gamer Engine and IR sensors!

Jaycie has been defying the laws of twisty-spatial-what’s-it’s with the Mirrix loom, warping it like a champ, battling (and winning) against the shedding device, and starting her first tapestry! Jaycie is the current Factory go-to for the looms, so schedule a consultation with her if you have an interest in these fantastic pieces of magic equipment and want to make a tapestry of your own!

Jaycie has been defying the laws of twisty-spatial-what’s-it’s with the Mirrix loom, warping it like a champ, battling (and winning) against the shedding device, and starting her first tapestry! Jaycie is the current Factory go-to for the looms, so schedule a consultation with her if you have an interest in these fantastic pieces of magic equipment and want to make a tapestry of your own!

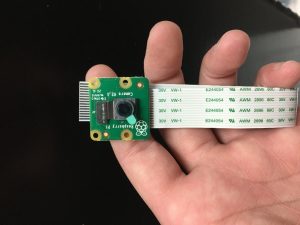

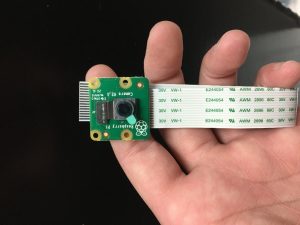

Jordan led her first (and packed!) DSLR workshop recently, wherein patrons learned the basic components of their camera, the specific bells and whistles of a DSLR, and the why’s/how’s for best use to take amazing pictures. She has also been working with Raspberry Pi, on photobooth for a certain love-centric upcoming holiday!

Jordan led her first (and packed!) DSLR workshop recently, wherein patrons learned the basic components of their camera, the specific bells and whistles of a DSLR, and the why’s/how’s for best use to take amazing pictures. She has also been working with Raspberry Pi, on photobooth for a certain love-centric upcoming holiday!

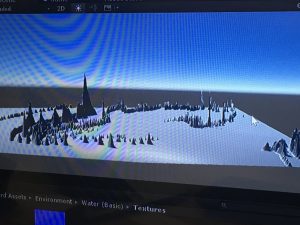

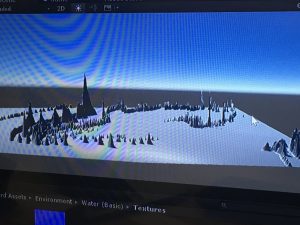

Nick has been working on lasercutting for patron work, which patrons (meaning anyone from the UNT/Denton community) can learn in the Lasercutting workshops that The Factory hosts! You can learn to format the .svg file necessary, learn about lasercutter setting and procedure, and learn how to schedule a consultation with a maker to get your project cut! Nick has also been working on an IR sensor theramin project, and teaching himself environment design in the Unity software.

Nick has been working on lasercutting for patron work, which patrons (meaning anyone from the UNT/Denton community) can learn in the Lasercutting workshops that The Factory hosts! You can learn to format the .svg file necessary, learn about lasercutter setting and procedure, and learn how to schedule a consultation with a maker to get your project cut! Nick has also been working on an IR sensor theramin project, and teaching himself environment design in the Unity software.

John has finished up the phase one of his HTC Vive flight simulator, which he built in Unity. Patrons are welcome to come in and play in the environment, propel yourself around, avoid (or aim for!) the objects in space, and play with the HTC Vive. John also began his weekly Unity Game Engine workshops, which are held Wednesdays from 7pm-9pm in the Factory workspace. If you want to learn how to make your own game, the Unity workshops will teach you the basic skills, and familiarize yourself with a wonderful software.

John has finished up the phase one of his HTC Vive flight simulator, which he built in Unity. Patrons are welcome to come in and play in the environment, propel yourself around, avoid (or aim for!) the objects in space, and play with the HTC Vive. John also began his weekly Unity Game Engine workshops, which are held Wednesdays from 7pm-9pm in the Factory workspace. If you want to learn how to make your own game, the Unity workshops will teach you the basic skills, and familiarize yourself with a wonderful software.

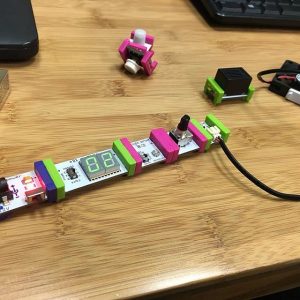

Little Bits are kind of like legos, but for circuits. They were designed with the beginner circuit builder in mind. They are a platform of easy-to-use electronic building blocks that empower you to invent anything, from your own remote controlled car, to a smart home device. The Bits snap together with magnets, no soldering, no wiring, no programming needed. Each little Bit has one unique function such as lights, sounds, sensors, buttons, and with different combinations you can make large circuits. Little Bits allow you to create interactive projects without any background in engineering, programming or wiring, in a few seconds. It’s as easy as snapping LEGO bricks together. And the best part is, its for free at UNT Factory!

Little Bits are kind of like legos, but for circuits. They were designed with the beginner circuit builder in mind. They are a platform of easy-to-use electronic building blocks that empower you to invent anything, from your own remote controlled car, to a smart home device. The Bits snap together with magnets, no soldering, no wiring, no programming needed. Each little Bit has one unique function such as lights, sounds, sensors, buttons, and with different combinations you can make large circuits. Little Bits allow you to create interactive projects without any background in engineering, programming or wiring, in a few seconds. It’s as easy as snapping LEGO bricks together. And the best part is, its for free at UNT Factory!

Also check out our Memory Craft 6500P sewing machine which is a computerized sewing and quilting machine. We also have small number of bobbins and Janome needles of varying sizes along with different types of presser feet and accessories.

Also check out our Memory Craft 6500P sewing machine which is a computerized sewing and quilting machine. We also have small number of bobbins and Janome needles of varying sizes along with different types of presser feet and accessories.

Shapeoko Machine: The CNC Shapeoko Machine is a milling tool available to mill common materials such as wood, plastics, soft/ non-ferrous metals, and a plethora of other materials. CNC, meaning Computer Numerically Controlled, together with a series of motors and drive components to move and control the machine axes, executing the programmed motions.

Shapeoko Machine: The CNC Shapeoko Machine is a milling tool available to mill common materials such as wood, plastics, soft/ non-ferrous metals, and a plethora of other materials. CNC, meaning Computer Numerically Controlled, together with a series of motors and drive components to move and control the machine axes, executing the programmed motions.

OtherMill Pro: The OtherMill Pro is a personal milling machine used to create PCB’s (Printed Circuit Boards) without the hassle of waiting for the board to be printed from an outside source. It also works with various materials such as wood and plastics, on a much smaller scale. The Othermill Pro is the fastest way to prototype high-precision PCBs in-house. Milling directly from Gerber files, the Othermill Pro handles double-sided PCBs with a variation of milling bits and can create your projects within minutes.

If you have a CNC project , you can submit a work request through The Factory website. Then an appointment will be scheduled with a Maker to train you on how to use the equipment to complete your project. Also, The Factory offers workshops on the topic.

The next CNC Easel Workshop For the Shapoko is schedule at 1pm on March 1, 2017. Registration is recommended to to limited sitting but not required.

OtherMill Pro: The OtherMill Pro is a personal milling machine used to create PCB’s (Printed Circuit Boards) without the hassle of waiting for the board to be printed from an outside source. It also works with various materials such as wood and plastics, on a much smaller scale. The Othermill Pro is the fastest way to prototype high-precision PCBs in-house. Milling directly from Gerber files, the Othermill Pro handles double-sided PCBs with a variation of milling bits and can create your projects within minutes.

If you have a CNC project , you can submit a work request through The Factory website. Then an appointment will be scheduled with a Maker to train you on how to use the equipment to complete your project. Also, The Factory offers workshops on the topic.

The next CNC Easel Workshop For the Shapoko is schedule at 1pm on March 1, 2017. Registration is recommended to to limited sitting but not required.