Hello! My name is Hanna Flores and I’m the team development coordinator at UNT’s makerspace. I am majoring in computer science, so a lot of my projects here at the makerspace center around computers and software. Even so, I love working with almost every machine we have in space. My mom sews all the clothes she wears, and my dad’s garage is really a woodshop where he makes whatever he thinks would be fun or useful around the house, so I come from a very creative family and my interests are very broad.

I love to sew, though I’m less inclined towards garments like my mom and more towards other kinds of projects like bags and other utility items. I learned to knit from my mom, and to crochet from my grandma, and it’s one of my favorite pastimes. On my own I learned tatting, which is a very convoluted way to make lace and one which I will never torture myself with again.

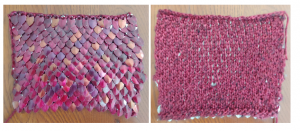

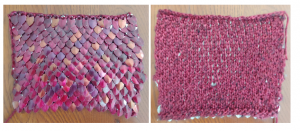

Included are pictures of some face masks I’ve been working on for work, and some hand knitted “scale-mail”, which is the process of knitting tiny metal scales into your work one by one. And yes I did hand paint each and every one of them with nail polish. Never again. My original plan was to knit a whole top out of them. That’s how far I made it before losing my mind.

I’ve worked with my dad in the garage since I was very little, so I really enjoy woodworking, especially building furniture because that’s what my dad taught me to make. Someday I want to try hand carving wood for decoration! This is a photo of the work bench I helped my dad make for his shop!

Now that I work in a place with even more advanced technology, I feel like I’ve become so much more creative. Through working here, I learned how to design models for 3D printing and then make the printers work to give me my materials. Below is a Mandalorian helmet I’m almost finished with, entirely 3D printed and finished with paint. Big huge enormous giant thank you to my coworker and one of my best friends, Kyle, for letting me use his personal printer for this!

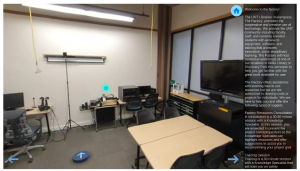

I’m also very lucky to use my love of software development at the makerspace by creating virtual 360 tours of both our locations using Unity These are both online now but not yet ready for public viewing yet, but here are some previews!

Working at the makerspace has been by far my favorite thing about going to university, both because of everything I’ve learned both creatively and professionally, but also because of the lifelong friends I’ve made here. To me, the makerspace feels like a family, and I have never been happier to know such an incredible group of people.

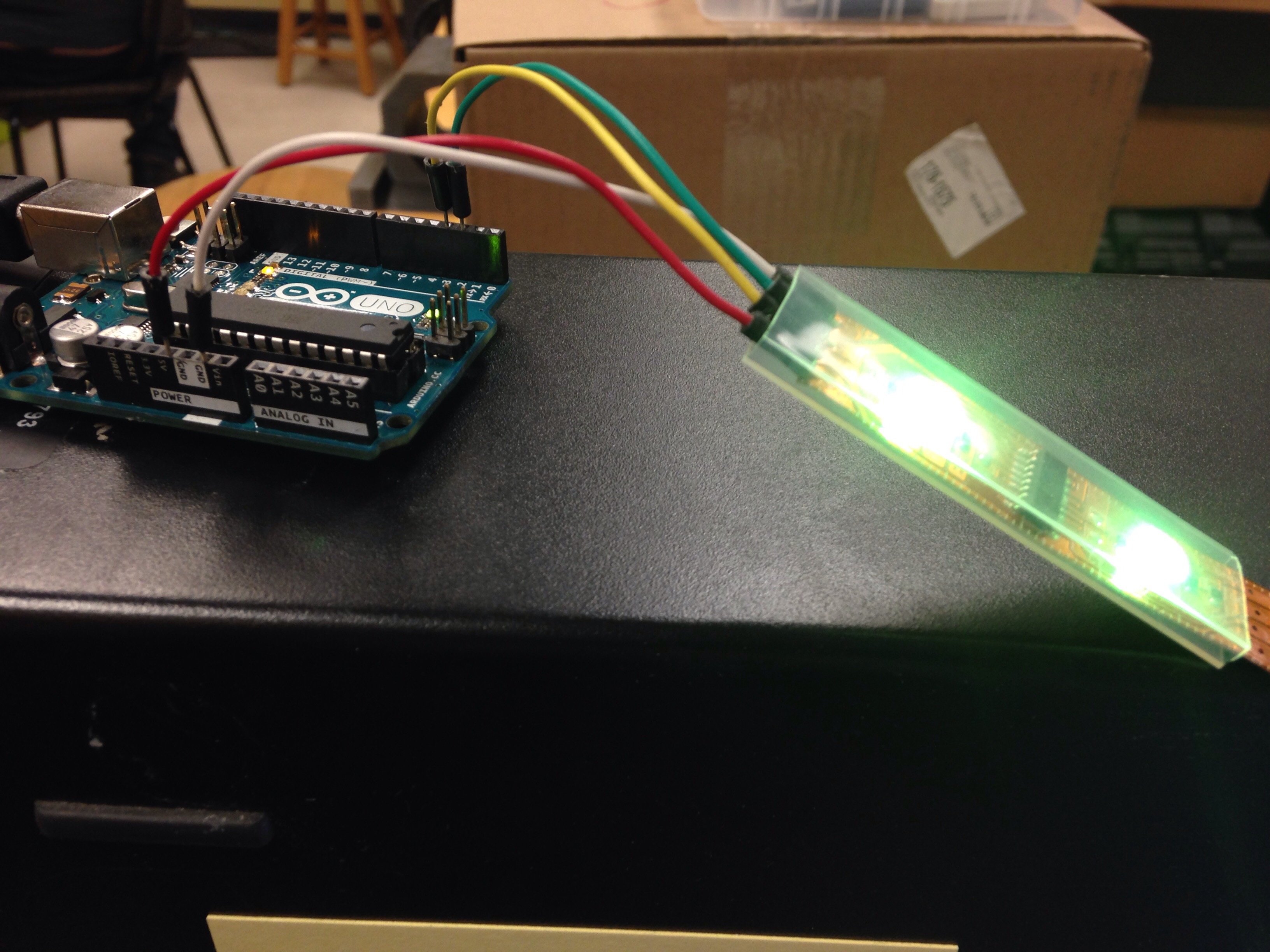

used on DIY which is what really peaked my interest.

used on DIY which is what really peaked my interest. and studio recording equipment as well. I also have a strong understanding in electronics and woodworking. I was attracted to the factory from my first time touring UNT in high school. I been an avid follower of the maker community and dreamed of being able to use a maker space, but I never imagined I’d be working at one. When I learned that they had a position open I was determined. For anyone, who may be curious about maker spaces I would have to say this is the friendliest environment I’ve ever been in. All the employees are very nice and are very willing to help guide you in creating or learning something new.

and studio recording equipment as well. I also have a strong understanding in electronics and woodworking. I was attracted to the factory from my first time touring UNT in high school. I been an avid follower of the maker community and dreamed of being able to use a maker space, but I never imagined I’d be working at one. When I learned that they had a position open I was determined. For anyone, who may be curious about maker spaces I would have to say this is the friendliest environment I’ve ever been in. All the employees are very nice and are very willing to help guide you in creating or learning something new.

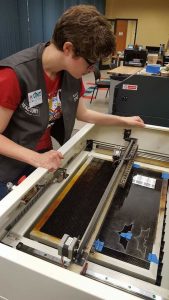

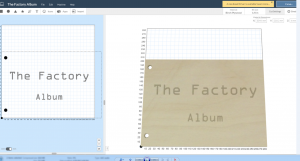

Maker Jordan is learning the CNC, in addition to her amazing photography skills, and working on a photo album for the Factory! The software for our Shapeoko CNC, Easel, shows her initial design.

Maker Jordan is learning the CNC, in addition to her amazing photography skills, and working on a photo album for the Factory! The software for our Shapeoko CNC, Easel, shows her initial design.

Finally, here are some cute designs [below] for the Cricut cutting machine by Maker Devin, who also just finished making a small purse [below] with the Factory sewing machines!

Finally, here are some cute designs [below] for the Cricut cutting machine by Maker Devin, who also just finished making a small purse [below] with the Factory sewing machines!