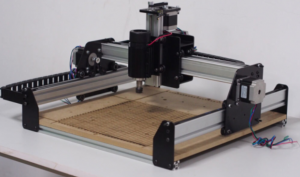

This blog post is about a CNC (Computer Numeric Control). When I joined the Makerspace, X-carve was called Shapeoko. It had a 500mm in XY and a 100mm in Z height. During the summer of 2019, I upgraded the Shapeoko to an X-Carve. It was a much better and efficient system. The upgrade involved taking apart Shapeoko completely and rebuilding from the ground up using different parts.

The main upgrade component was the drivers and the board for the CNC. The X-controller had motor divers and a motherboard built-in, which made the build a little easier. Then, we used stronger and better aluminum profiles to replace the current ones. The new profiles had dual rails so it can run two V-groove wheels on both sides. This improves precision and reduces friction within the axis.

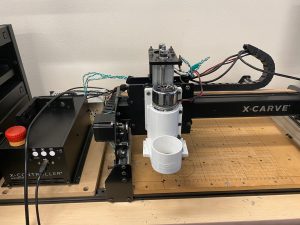

Lastly, I used a 48V independent spindle. This makes it easier to control the spindle. Spindle specs are so much better than the standard X-carve spindle. The standard running RPM is 12,000. The upgrade is complete as of now, and X-carve had its first project lined up while it was in the works. UNT Libraries requested 50 Power outlet faces milled. X-carve successfully completed the whole project just after the day that it was built.

Lastly, I used a 48V independent spindle. This makes it easier to control the spindle. Spindle specs are so much better than the standard X-carve spindle. The standard running RPM is 12,000. The upgrade is complete as of now, and X-carve had its first project lined up while it was in the works. UNT Libraries requested 50 Power outlet faces milled. X-carve successfully completed the whole project just after the day that it was built.

Written By: T. Weerasinghe