What is FDM Printing?

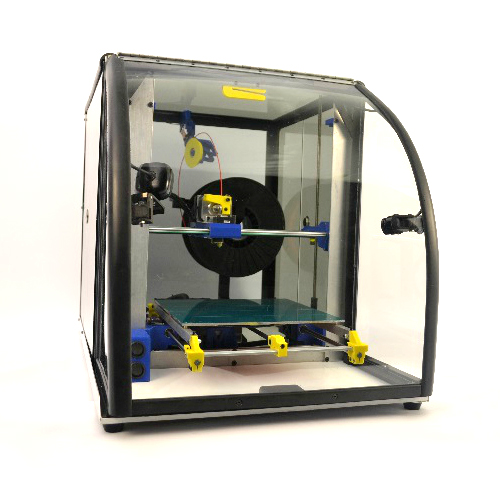

FDM printing is the most common method of 3D printing. It is the easiest to learn and is the most cost-effective way to print. FDM printing stands for Fusion Deposition Modeling. It is also commonly referred to as FFF, which stands for Fused Filament Fabrication. Both FDM and FFF are the same process, and the terms are interchangeable. The actual process involves melting a spool of plastic material at high temperatures through a nozzle that travels along a specific path to model the object you are printing. This path is created by G-code, a list of coordinates that tell the nozzle where to go and when.

Advantages:

The most considerable advantage of FDM printing is its price. It is very cheap to print using FDM printing. A good hobby printer costs about $250, and material can cost $20 per spool, which gives you 1kg of material. FDM printing is very friendly to people who are new to 3D printing, which is one of the main reasons it is so popular. All the user needs to do is load the object into the slicing software (so the printer knows what to do with the object), press print, and give the printer time to make your part. If the objects you want to print are for practical purposes, FDM prints are stronger than SLA prints, which allows them to last much longer.

Disadvantages:

Because FDM printers are so popular, there are countless different printers from which to choose. All these options can make it hard to decide what printer to buy, and they vary widely in usability from one to the other. FDM printers can also be a bit finicky, depending on the printer, causing you to spend time fine-tuning it. Many variables, like the software settings, mechanical aspects, maintenance, and even the climate of the room, can all affect how your printer runs to get a successful print. There are also many different types of filaments that require higher temperatures, heated beds, enclosures for the printer, and stronger filaments that can even wear down the printer’s internal components. Not all printers can print with every filament type, so be aware of the limitations of your printer. Some brands will mention the specific filaments their printers can print with, which is something to keep in mind depending on what you want to do with a printer.

What is SLA Printing?

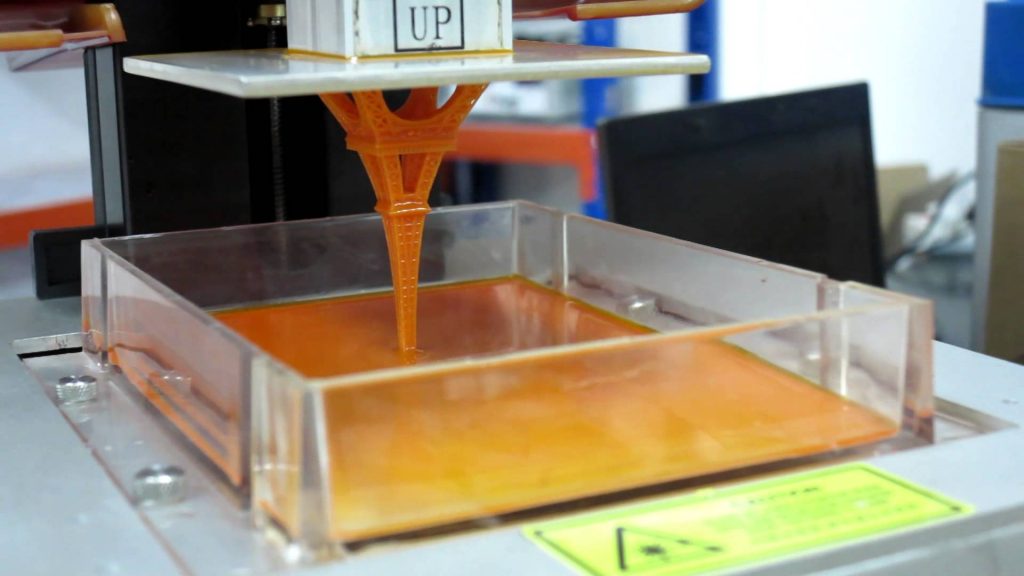

SLA printers are quickly growing more accessible since the price of these printers is getting cheaper. A few years ago, a reliable SLA printer would have cost roughly $2000, but now an SLA printer that can produce high-quality prints costs about $300.

This method of printing involves a pool of resin rather than plastic cured by ultraviolet light. The light is projected by an LCD screen below the resin pool, curing the resin at each cross-section. The printer will then peel the cured layer off the base to let fresh, uncured resin flow under the object allowing the light to cure the next layer. Because this method cures material, rather than depositing material layer by layer, SLA printing enables you to achieve much greater detail in the object than what you might be able to get out of FDM printing.

Advantages:

SLA printing is the way to go for objects with high detail, steep overhangs, and intricate parts. SLA can also achieve much greater detail in layer height, to the point where layers are nearly indistinguishable. Most of the applications for SLA include miniatures, jewelry, and highly complex objects. This printing method is the best choice for aesthetic prints.

Disadvantages:

The printer itself is quite loud, given the fan needs to work hard to keep the electronics from overheating. The resin used to make the prints has a very potent smell, causing you to need a well-ventilated area for the printer when using it. When the print is complete, it needs to go through an acetone bath to remove the uncured resin and be placed in a UV curing station to improve its strength. These added steps to post-processing are not needed with FDM printing and require extra materials that need to be purchased. The prints themselves, though very high detailed, are not very strong. SLA prints cannot withstand stress well before they break, so if the object goes under any consistent strain, it will not last long. SLA prints are also sensitive to UV light, so if they are exposed to the sun for an extended time, they will become brittle and degrade.

Of course, there are more methods to 3D printing than just these two, but since they are the most common, they are the most reasonable to discuss. There are many more advantages and disadvantages to both FDM and SLA printing, but both are perfectly effective for 3d printing for different needs and purposes. When deciding which method is the best for you, look at what you need to print, what its purpose is, and the limitations that either method possesses to produce your intended object effectively.

Written By: K. Mortensen