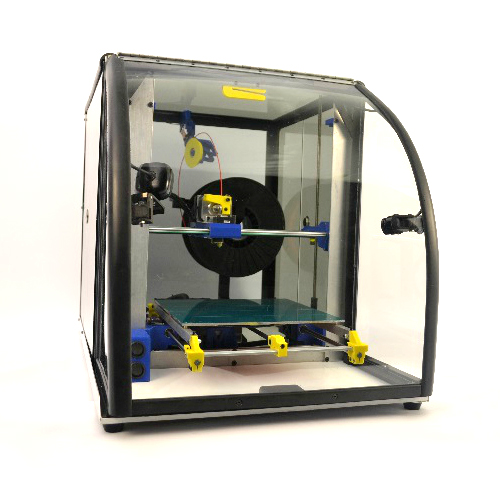

The Lulzbot TAZ 3D printers are one of the most user-friendly printers on the market. The first two printers in the LulzBot 3D Printer cluster were Prusa RepRaps put together with printed parts purchased off the Internet. They were built in the first quarter of 2011. These two printers printed the next set of parts needed by the subsequent LulzBot Prusa Clonedels.

LulzBot was founded in 2011 by the parent company Aleph Objects. Their fully open-source workhorses are renowned for their robust design and reliability, though their high prices have largely kept them off the individual hacker’s bench. While the printers did not do well in the consumer market, it did exceptional in the industrial market. The reliability of their machines got them to be used by the United States Marines. The open-source system led it to be used by The National Aeronautics and Space Administration. NASA uses a modded Lulzbot TAZ 4 to 3D print tools on the International Space Station.

Though the Lulzbot TAZ printers had short success in the industrial and commercial field, consumers did not want to spend a grand on a desktop printer when there were better, cheaper options. Due to this, in 2018, the company announced that there were many layoffs in the company. This came in correlation with bad financials following the first quarter of that year. An email attributed to Aleph Objects states, “We regret to inform you that the owners of Aleph Objects Inc, makers of Lulzbot 3D printers, have decided to close down the business as of Wednesday, October 9th, 2019. Operations will continue through October 31st, 2019 to sell through existing inventory.” Of the company’s 113 employees, only 22 would remain onboard to maintain day-to-day operations.

Following the speculation that Aleph Objects, manufacturer of Lulzbot open-source 3D printers had met its end, the company has refused to deny claims that it is indeed shutting down. Some insiders said they had heard expected a buyout, and soon the sale of Aleph Objects to Fargo Additive Manufacturing Equipment 3D (FAME 3D) became official.

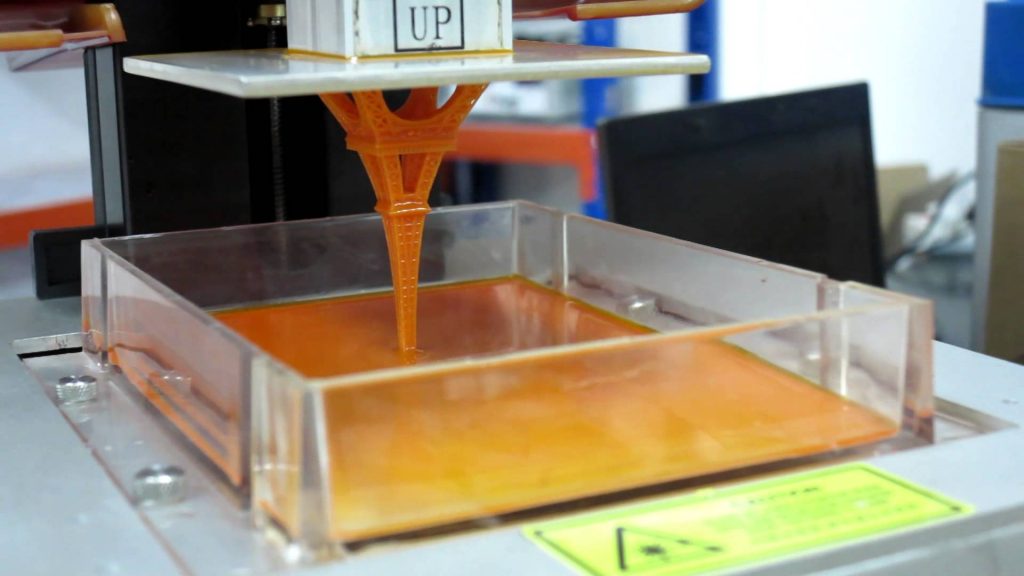

This new financial backing certainly is good news, but it would be naive to think this is the end of LulzBot’s troubles. The community has made it clear that cheaper and more accessible desktop printers are more attractive. The company has said they are willing to create a new, more affordable option to their printers. Though Lulzbot’s company has had issues internally, the projects such as its entry into the 3D bioprinting market in early 2018 may keep the printer’s name afloat.

Written by: P. Friedman