Makerspaces are a technology-focused subset of the DIY culture. Before Makerspaces, there were what are known still as “hackerspaces”, which were first organized in Germany. The idea of a physical gathering of hackers spread to the United States via interaction at a conference, and the first United States hackerspaces were founded (some still in operation) in New York City.

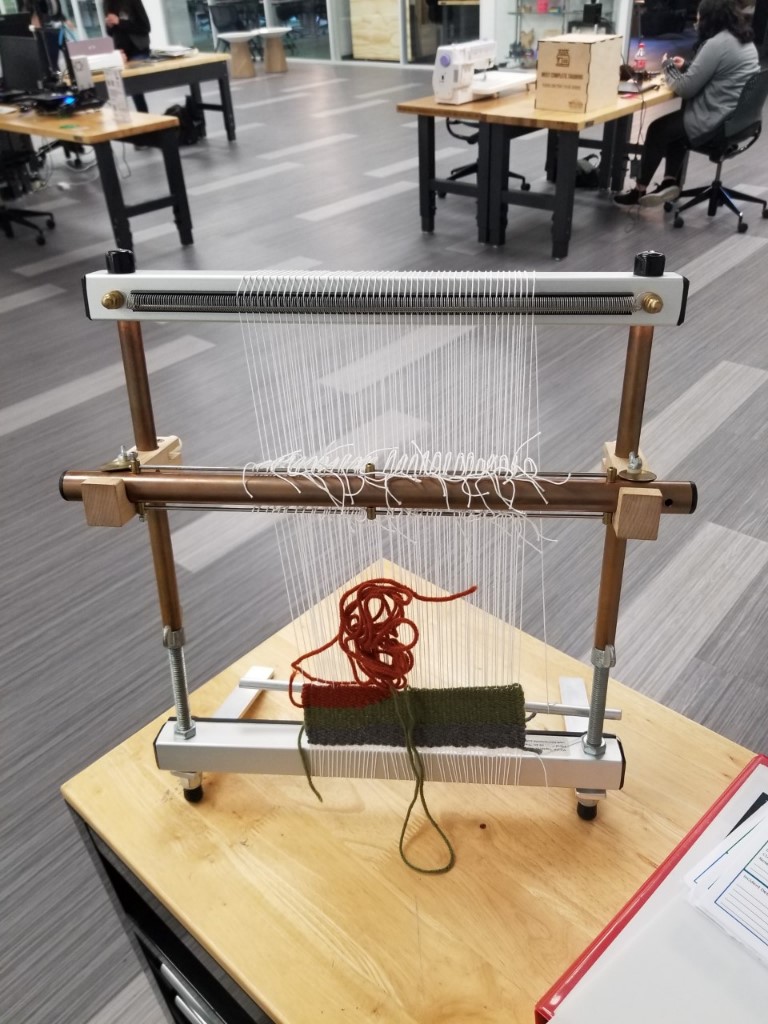

Eventually, there came to be a division between what some hackerspaces were hosting; some stayed focused on hacking, altering electronic components for other purposes, and innovating on boards and code. Others chose to integrate other interests, with interests in design, woodcutting, sewing/textiles, metal-smithing, etc. These spaces became known by the term “makerspace”, where members could physically meet, collaborate, and work together outside of a narrow context like their jobs, single skills set, or group.

Makerspaces are inherently inclusive, innovative, and educational. And a serious plus is that now people don’t have to buy and store things like giant laser cutters, CNC milling machines, and 3d printers in their homes! The original feeling of the hacker culture, that agency to play and change something, mixed with the hands-on myriad of other material and skills interests found in the DIY culture, culminating in makerspaces like the Spark at UNT!

The maker movement has been growing in education from k-12 through college and the public sector. The interesting and challenging aspect of a maker space is that they are grouped together around an ideology more so than a specific physical make up. Makerspaces, are generally agreed to be a social or lab space dedicated to the process of hands on learning, tinkering, investigating and making. Makerspaces can have a wide range of setups and therefore the definition can be just as varied:

Laura Fleming – “A makerspace is a metaphor for a unique learning environment that encourages tinkering, play and open-ended exploration for all.”

Diana Rendina – “A makerspace is a place where students can gather to create, invent, tinker, explore and discover using a variety of tools and materials.”

John J Burke – “A makerspace is an area in a library where users can use tools and equipment to design, build, and create all sorts of different things. It may be a dedicated room or a multipurpose space in which a collection of raw materials and resources can be utilized as desired. Projects range from prototyping product designs with 3D printers, to programming robots, to creating art out of recycled items.”

Colleen Graves – ” A makerspace is not only a place where you can make stuff but many times its a place where you make “meaning” which many times is more important than the stuff you make.”

Ann Smart – “A space with materials for students to let their curiosity and imagination come to life. An informal, playful, atmosphere for learning to unfold. A space where making, rather than consuming is the focus. A space where trans-disciplinary learning, inquiry, risk-taking, thinking, crafting, tinkering, and wondering can blossom.”

TheRSA.org – “Makerspaces are open access workshops hosting a variety of new and old tools – from 3D printers and laser cutters to sewing machines and soldering irons. Makerspaces are more than just sites to craft objects. They are also places to experiment with a different way of living – one that responds to the challenges and opportunities of a world in which technology is ubiquitous.”

i3Detroit.com – A Makerspace is “a collision of art, technology, learning, and collaboration”

Mad-Learn.com – “A makerspace is a place that provides creative time and space for people of all ages to build prototypes, explore questions, fail and retry, bounce ideas off one another and build something together. These spaces don’t always include technology, since some prototypes and designs can be built out of anything or may include various stages of design that move from analog to digital and back again, but many do include technology. Now, with 3D printing and design, makerspaces are really taking off. Kids gather in a common area to design and ideate on 3D printing projects. The makerspace becomes a safe area where creativity and risk-taking becomes common practice.”

Techtarget.com – “A makerspace is a community center that provides technology, manufacturing equipment and educational opportunities to the public. Makerspaces allow community members to design, prototype and manufacture items using tools that would otherwise be inaccessible or affordable such as 3-D printers, digital fabrication machines and computer-aided design (CAD) software. Makerspaces are typically funded by membership fees or through affiliations with external organizations, such as universities, for-profit companies, non-profit organizations and libraries. The free exchange of ideas and resources is a central tenet of makerspaces. Often, members of different makerspaces will collaborate on projects and share knowledge at gatherings known as build nights or open-house days.”

Bozeman Makerspace – “A Makerspace / Hackerspace allows groups of people to pool resources and create a community of people with varied interests. These interests may include but are definitely not limited to: circuitry, robotics, soldering, woodworking, fabricating, programming, networking, hacking, bending, etc.”

Room 6KGH.com – “A makerspace is simply a place where people gather and make. They come all shape and size. A makerspace is a student centered learning environment with limitless possibilities.”

Educause.edu – “Makerspaces are zones of self-directed learning. Their hands-on character, coupled with the tools and raw materials that support invention, provide the ultimate workshop for the tinkerer and the perfect educational space for individuals who learn best by doing…they promote multidisciplinary thinking and learning, enriching the projects that are built there and the value of the makerspace as an educational venue.”

Libraries & Maker Culture – “Makerspaces which are sometimes called hackerspaces–can be any area where people gather to make and create. These spaces often include 3D printers, but do not necessarily have to. In makerspaces, people share supplies, skills, and ideas, and often work together on projects. Makerspaces grew out of maker culture–a group of people dedicated to craftsmanship and creation. Makerism focuses on DIY projects, and makers value creation by individuals or small groups rather than bulk production. In general, makerism is also a culture of creation over consumption.”

Library as Incubator – “Makerspaces are collaborative learning environments where people come together to share materials and learn new skills. Makerspaces are not necessarily born out of a specific set of materials or spaces, but rather a mindset of community partnership, collaboration, and creation. ”

OEDB.org – Makerspaces, sometimes also referred to as hackerspaces, hackspaces, and fablabs are creative, DIY spaces where people can gather to create, invent, and learn. In libraries they often have 3D printers, software, electronics, craft and hardware supplies and tools, and more.

am a biochemistry major in my third year at UNT with minors in biology and technical writing. I first discovered the Factory as part of a job search after I decided that I NEEDED to get out of previous call center job, and I’ve been working here as a Maker for going on three years now. I’ve worked in “hands-on” workplaces before but never one that focused on DIY which is what really peaked my interest.

am a biochemistry major in my third year at UNT with minors in biology and technical writing. I first discovered the Factory as part of a job search after I decided that I NEEDED to get out of previous call center job, and I’ve been working here as a Maker for going on three years now. I’ve worked in “hands-on” workplaces before but never one that focused on DIY which is what really peaked my interest.