Written by: S. Pokala Spark TEK Specialist UNT Graduate Information Technology and Decision Sciences

My name is Susmitha, and I’m a Business Analytics graduate student at UNT studying Information Technology and Decision Sciences. Every step of the way, I was inspired to create a novel information processing architecture, and I made sure to devise a novel technique that decreased manual work because that is the essence of engineering.

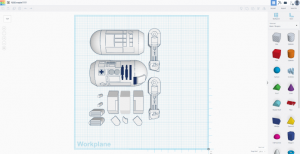

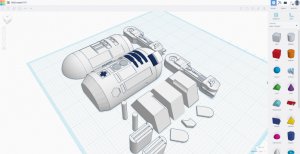

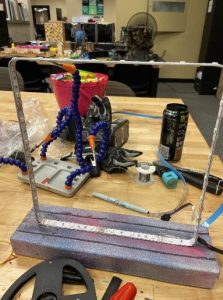

I am an Electronics and Communications graduate, and one of the projects I built for my course work was an ultrasonic sensor-based application (Arduino) that would activate an alert within the device if an obstruction appeared in front of it, signaling the presence of the obstacle. This initiative was created with the goal of preventing blind people from becoming involved in traffic accidents. The Spark Makerspace has provided me with invaluable opportunities to share my skills with my peers. It’s been a fantastic opportunity for me to acquire new skills and techniques in Arduino and Raspberry Pi 4. I’m still attempting to master all of the new tools accessible in Spark Makerspace, such as LittleBits, project planning, 3D modeling, and printing. Spark’s Makers are quite pleasant to work with and patient in guiding you through the process. I recently 3D built a PubG helmet and am eager to learn about all of the additional tools and equipment that are available. My hobbies include traveling and experiencing various cuisines. I used to travel a lot when I worked in IT, but I haven’t had much chance to visit the United States yet.

The Spark Makerspace is an excellent resource for UNT students who wish to pursue their interests and creativity in both their personal and professional lives. This location is brimming with information and specialists from a variety of fields. Our Spark family always extends a warm welcome to you. Come in and take advantage of our resources to achieve your goals.

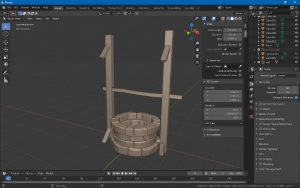

Hello! My name is Mikey Heins and I am a junior Fine Arts major concentrating in Photography here at UNT. My passions are art and technology, and I love combining the two whenever possible. I have always been interested in tinkering, making, and learning, with fond memories of staying up late as a kid watching the legendary Make Magazine instructional videos on YouTube. I spent many hours in my youth working on projects on my bedroom floor (as indicated by the many stains, dried glue, and burns on that poor carpet), ranging from circuitry, woodworking, and crude robots. I got my first Raspberry Pi (a teeny credit-card sized computer) around 6th grade, opening the doors to the magic of programming! I joined a First Robotics Competition team during my freshman year of high school, which is where I believe I grew and learned the most. For all four years, I worked endlessly with my team to create from scratch, our very own robots to compete in difficult challenges.

Hello! My name is Mikey Heins and I am a junior Fine Arts major concentrating in Photography here at UNT. My passions are art and technology, and I love combining the two whenever possible. I have always been interested in tinkering, making, and learning, with fond memories of staying up late as a kid watching the legendary Make Magazine instructional videos on YouTube. I spent many hours in my youth working on projects on my bedroom floor (as indicated by the many stains, dried glue, and burns on that poor carpet), ranging from circuitry, woodworking, and crude robots. I got my first Raspberry Pi (a teeny credit-card sized computer) around 6th grade, opening the doors to the magic of programming! I joined a First Robotics Competition team during my freshman year of high school, which is where I believe I grew and learned the most. For all four years, I worked endlessly with my team to create from scratch, our very own robots to compete in difficult challenges.

am a biochemistry major in my third year at UNT with minors in biology and technical writing. I first discovered the Factory as part of a job search after I decided that I NEEDED to get out of previous call center job, and I’ve been working here as a Maker for going on three years now. I’ve worked in “hands-on” workplaces before but never one that focused on DIY which is what really peaked my interest.

am a biochemistry major in my third year at UNT with minors in biology and technical writing. I first discovered the Factory as part of a job search after I decided that I NEEDED to get out of previous call center job, and I’ve been working here as a Maker for going on three years now. I’ve worked in “hands-on” workplaces before but never one that focused on DIY which is what really peaked my interest.